Ni-GripTM

Friction Shims

Surface Technology, Inc. is your source for friction shims. STI manufactures diamond coated friction shims in:

- Any shape or size

- Any thickness

- Any base metal

- Any roughness

- Large or small quantities

Custom Metal Shims with a Diamond Coating

Creating a Coefficient of Friction That Grips Tight

.png.aspx)

Ni-GripTM Friction Shims are used in countless applications in the automotive, aerospace, wind energy, turbine, machining equipment, robotics, medical, dental, paper and many other industries. These flat ring shims increase the friction, grip, torque, energy transfer and other critical properties of these applications. Ni-GripTM Friction Shims are especially useful in mechanical assemblies, as electric motor shims, as torque converter shims, for transmission applications, drive systems and axle shim assemblies where exact alignment is important.

Examples of the many shapes and sizes of Ni-GripTM Friction Shims available

Ready to use Ni-GripTM Friction Shims from STI are available in steel, stainless steel, or aluminum shim base metals with any version of STI's Composite Diamond Coatings (CDC) depending the level of grip required. You may also send us your own friction shims, and STI can coat them with any version of CDC you require.

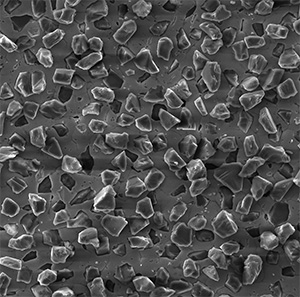

Ni-GripTM Friction Shims contain millions of diamond particles protruding from a uniform nickel alloy coating. These exceptionally hard diamonds grip into the surfaces of the mating material in an assembly and enable up to about 5 times higher torque while stabilizing alignment.

The surface of a Ni-GripTM Friction Shim and the high-performance diamond

Custom Friction Shims Enhance Torque Transfer and Joint Integrity with Ni-GripTM Friction Technology

Our custom friction shims are engineered to increase surface friction in bolted joints—helping manage shear forces, prevent slippage, and potentially eliminate the need for oversized fasteners or components. By integrating these into your assembly, you can boost torque transfer by up to 5x, especially in high-performance systems where weight and space are critical factors.

For applications like robotic assemblies and precision machinery, our custom shims deliver reliable performance and design flexibility. Whether you require slotted metal shims, tapered metal shims, or other specialized profiles, we can manufacture to your exact specifications and apply our patented Ni-GripTM friction coating for consistent, high-friction performance.

When reducing noise and vibration is key, our electric motor shims and thin metal shims are ideal solutions. These components are engineered to minimize vibration and improve system stability in dynamic environments.

From concept to production, we partner with your team to develop tailored solutions that meet your mechanical and performance demands—down to the last micron.

Electroless Nickel Plating with our Patented Formulas

This is in addition to friction and grip, the diamond coating on Ni-GripTM Friction Shims provide:

- Exceptional hardness

- Corrosion resistance

- Perfect conformity to complex geometries

- Wear, abrasion, impact, and high temperature resistance

These features allow:

- Greater reliability and consistent performance

- Opportunity to re-engineer products with lighter weight and/or less expensive materials

- Energy savings

Surface Technology, Inc. has been the world leader in diamond coatings, as you can see from our company history. STI incorporates decades of experience into the Ni-GripTM Friction Shims we manufacture. Our Friction Shims are used in space, underground, and on all types of vehicles and equipment on Earth.

The coatings applied by STI to your Ni-GripTM Friction Shims have received a positive review from the U.S. Food and Drug Administration (FDA), Department of Health and Human Services. Click here for details. Ni-GripTM Friction Shims are manufactured in STI’s solar powered, environmental award winning facility. Click here for details. We use only the highest quality plating chemicals, also developed and manufactured by STI for ultimate quality, consistency, and economy of the coatings applied to these friction shims.

Ni-GripTM Friction Shims are covered by one or more of the following United States Patents: No. 4,997,686, 5,145,517, 5,300,330, 5,863,616, 6,306,466, 7,744,685, 8,147,601, 8,598,260, 9,096,924, 10,006,126, 10,731,257, and 10,731,258.

Surface Technology Inc is the inventor of several patents including

Some of Our Electroless Plating Patents

US-7744685-B2 on Unified Patents

US-8147601-B2 on Google Patents

Composite PTFE Plating as found on Google Patents

High Quality Plating Bath Solutions as found on Google Patents

And we are the inventor of

Composite Diamond Coatings used by plating companies around the globe.