Products & Services

Creator of Composite Diamond Coating®

Surface Technology, Inc. is the creator and technical leader of CDC - Composite Diamond Coating®, an exceptionally engineered coating of electroless nickel with fine diamond. The synergy of these materials makes CDC an exceptionally hard and wear resistant coating. CDC conforms to even the most complex geometries and is an excellent replacement for chrome plating. STI makes CDC available via coating services from its production facility as well as chemical products sold directly, through a network of distributors, and by agreement with licensees worldwide.

Contact STI for One-Plate® Electroless Nickel solutions, the simplest EN in the world. These One-Plate® systems use just one “Q” solution for both bath make-up and replenishment. This innovation by STI overcomes the many shortcomings of using three A, B, and C solutions. Available in low, medium, high phosphorous, and composite EN varieties. Naturally, all are RoHS compliant.”

Chemical Deburring & Polishing

Surface Technology, Inc. has developed two revolutionary processes for chemical deburring and polishing.

Deburr 1000™ is used for deburring carbon steel

Deburr 2000™ is used for deburring stainless steel

Both of theses unique electroless chemical processes remove burrs on parts which are created by cutting, milling, forging, molding and additive 3D printing, without distorting even the most intricately shaped parts.

STI Deburr processes provide numerous advantages over conventional deburring methods such as grinding, polishing, thermal, and electrolytic deburring which require excessive manual labor time and additional costs. These economical and reliable processes will not damage sensitive surfaces often caused by tumbling and grinding operations.

Deburr 1000™ and 2000™ can be used in two ways:

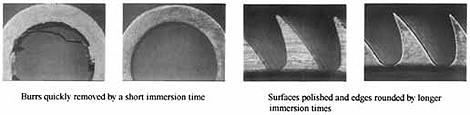

- Short immersion times quickly sever burrs from the workpiece at their base. The burrs then fully dissolve in the bath. Reproducibility of material removal is as low as 0.5 micron.

- Longer immersion times polish, shape, and round the edges of precision parts. Surfaces can be polished to a peak-to-valley height of 0.1 micron.

Achieving these outstanding surface characteristics has proven especially useful for parts in a wide range of applications and industries. Smoother and rounder surfaces on these parts provide greater reliability and longer life for these parts as well as less damage to other parts and materials that make contact with the deburred parts.

Deburr 1000™ processes leave parts clean and ready for immediate use, or for subsequent surface finishing operations, including plating and any of STI's electroless nickel coatings, if desired.

The Deburr 1000™ technology is available from STI:

- As a coating service from STI’s production facility onto your parts, and

- In chemical products from STI for customers to use in their own facilities.

These chemical components are formulated for maximum reliability, convenience, and economy; and are backed up by STI’s first hand practical knowledge of their operation.