Products & Services

Creator of Composite Diamond Coating®

Surface Technology, Inc. is the creator and technical leader of CDC - Composite Diamond Coating®, an exceptionally engineered coating of electroless nickel with fine diamond. The synergy of these materials makes CDC an exceptionally hard and wear resistant coating. CDC conforms to even the most complex geometries and is an excellent replacement for chrome plating. STI makes CDC available via coating services from its production facility as well as chemical products sold directly, through a network of distributors, and by agreement with licensees worldwide.

Contact STI for One-Plate® Electroless Nickel solutions, the simplest EN in the world. These One-Plate® systems use just one “Q” solution for both bath make-up and replenishment. This innovation by STI overcomes the many shortcomings of using three A, B, and C solutions. Available in low, medium, high phosphorous, and composite EN varieties. Naturally, all are RoHS compliant.”

High Friction Coatings

Demand for high friction surfaces is growing rapidly in a wide number of industries. Surface Technology, Inc. has developed the most extensive selection of high friction composite electroless nickel coatings to serve the needs of applications in the automotive, aerospace, wind energy, turbine, machining, robotics, medical, dental, paper and many other industries.

STI’s high friction coatings are used on shims, flanges, bolts, connectors, clamps, collets, joints, belt applications, and more. These coatings work to increase the friction, grip, torque, energy transfer and other critical properties of these applications. Friction shims are especially useful in assemblies and applications.

Ready to use Ni-GripTM CDC Friction Shims are available from STI. These are available in standard sizes or custom designed to serve your specific application. STI can also apply any of our CDC high friction and grip coatings to shims you supply in any size, shape, or base metal.

Ready to use Ni-GripTM Friction Shims from STI are available in steel, stainless steel, or aluminum base metals with any version of STI's CDC Composite Diamond Coatings depending the level of grip required.

Ni-GripTM Friction Shims contain millions of diamond particles protruding from a uniform nickel alloy coating. These exceptionally hard diamonds grip into the surfaces of the mating equipment in an assembly, and enable up to about 5x greater torque.

This is in addition to all the features inherent in all our coatings, including:

- Exceptional hardness

- Corrosion resistance

- Perfect conformity to complex geometries

- Wear, abrasion, impact, and high temperature resistance

- Applicability to many common metals and alloys

- Coverage of entire surfaces or selected critical areas

These features allow:

- Greater reliability and consistent performance

- Increased lifetime and decreased maintenance-related downtime

- Opportunity to re-engineer products with lighter weight and/or less expensive materials

- Energy savings

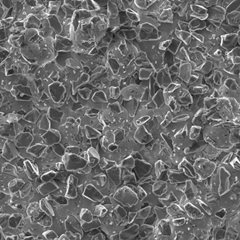

Our high friction coatings all work thanks to the roughness achieved by the protrusion of hard particles such as diamond, silicon carbide or others through the surface of an electroless nickel coating as seen in the following SEM photograph. These hard particles then grip into the mating surface. STI can vary the roughness by adjusting the size, shape, and density of the particles on the surface. We test all of our formulations in our electroless nickel coating job shop in New Jersey while serving clients in New York, Pennsylvania, USA and around the world.

SEM photograph of the surface of a CDC-25 coating

SEM photograph of the surface of a CDC-25 coating

TYPICAL HIGH FRICTION COATING PROPERTIES

Additional versions available from STI to meet the specific needs of unique applications

| Property |

CDC®-8 |

CDC®-25

LD |

CDC®-25

HD |

CDC®-40 LD |

CDC®-40 HD |

CDC®-50 |

| Particle |

Diamond |

Diamond |

Diamond |

Diamond |

Diamond |

Diamond |

| Particle Size |

8 µ |

25 µ |

25 µ |

40 µ |

40 µ |

50 µ |

| Particle Concentration by Volume |

30-40% |

10-25% |

25-50% |

10-30% |

25-50% |

25-50% |

| EN Alloy Hardness (HV) |

550-900 |

550-900 |

550-900 |

550-900 |

550-900 |

550-900 |

| EN Thickness |

5-500 µ |

10-20 µ |

15-30 µ |

15-25 µ |

20-30 µ |

20-30 µ |

| Coating Thickness |

5-500 µ |

22-38 µ |

27-48 µ |

35-55 µ |

40-60 µ |

45-70 µ |

| Roughness |

0.65 µ |

3.4 µ |

6.9 µ |

4.0 µ |

7.7 µ |

8.5 µ |

Note: LD = Low Diamond Density and HD = High Diamond Density

STI is pleased to make these coatings available:

- As a coating service from STI’s production facility onto your parts, or

- In chemical products from STI to be applied in your own facilities.

All of STI’s high friction coatings have received a positive review from the U.S. Food and Drug Administration (FDA) Department of Health and Human Services. Click here for details.

These coatings may be covered by one or more of the following United States Patents No. 4,997,686, 5,145,517, 5,300,330, 5,863,616, 6,306,466, 7,744,685, 8,147,601, 8,598,260, 9,096,924, and 10,006,126