Creator of Composite Diamond Coating®

Surface Technology, Inc. is the creator and technical leader of CDC - Composite Diamond Coating®, an exceptionally engineered coating of electroless nickel with fine diamond. The synergy of these materials makes CDC an exceptionally hard and wear resistant coating. CDC conforms to even the most complex geometries and is an excellent replacement for chrome plating. STI makes CDC available via coating services from its production facility as well as chemical products sold directly, through a network of distributors, and by agreement with licensees worldwide.

Contact STI for One-Plate® Electroless Nickel solutions, the simplest EN in the world. These One-Plate® systems use just one “Q” solution for both bath make-up and replenishment. This innovation by STI overcomes the many shortcomings of using three A, B, and C solutions. Available in low, medium, high phosphorous, and composite EN varieties. Naturally, all are RoHS compliant.”

Nano-Plate™

New technological advances have generated an unprecedented interest in nano-sized materials. This technology has potential opportunities in numerous industries for countless advanced applications. This interest derives from the unique properties inherent in materials sized in the range of nanometers.

Surface Technology, Inc. has applied its expertise in composite coatings to incorporate nano-sized materials. After more than a decade of research and development, composite electroless coatings with nano-sized particles are now commercially available from Surface Technology, Inc. These innovative coatings feature:

- High hardness

- Exceptional wear resistance

- Excellent corrosion resistance

- Enhanced thermal transfer

- Unique surface characteristics

- Conformity to all shapes and sizes including non-line of sight applications

- Coverage of entire surfaces or selected critical areas

- Applicability to many metals and alloys

Nano-Plate™ has received a positive review from the US Food and Drug Administration (FDA) Department of Health and Human Services. Click here for details.

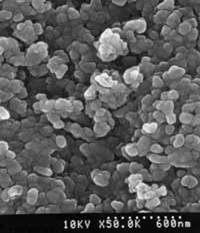

Incorporating fine diamond particles in nanometer sizes means a tremendous increase in diamond surface area within the composite, yet with few automorphic or cleavage faces thanks to the generally rounded surfaces of these advanced particles. The resulting composite is compatible with a wide array of mating materials including textiles, paper, plastics, seals, metals, and alloys.

Following are Taber abrasion test results for Nano-Plate™ 150 and hard chrome plating. In the Taber test method, a coated panel turns under two rotating abrasive wheels. Wear is measured as the weight loss of the panels following a specified number of rotating cycles. The lower the wear index, the lower the wear to the coating. The following results are based on an extensive test of 10,000 cycles.

| Material |

Wear Index

|

|

Nano-Plate™ 150

|

0.0013

|

|

Hard chrome plating

|

0.04

|

Other test methods also demonstrate the tremendous advantage of Nano-Plate™ coatings for wear resistance over hard chrome plating as well as other materials such as flame-sprayed aluminum oxide. The following are the results of the Yarnline Abrasive Wear Test where an abrasive yarnline under constant tension is drawn across a material sample at a constant speed and force against the test piece. Results are measured in material removal over time as mil3 per hour.

| Material |

Wear Index

|

|

Nano-Plate™ 150

|

3.2

|

|

Flame spray aluminum oxide

|

173.6

|

|

Hard chrome plating

|

3478.8

|

In addition to these exceptional performance advantages over chrome plating, Nano-Plate™ is free of the environmental issues confronting chromium plating processes and deposits. Nano-Plate™ coatings can also be chemically stripped, allowing the continual reuse of parts.

Scanning Electron Micrograph of Nanometer Diamond Particles as Incorporated in Nano-Plate™

Nano-Plate™ is covered by one or more of the following United States Patents No. 4,997,686, 5,145,517, 5,300,330, 5,863,616, 6,306,466, 7,744,685 and 8,147,601.